Download: U2 Knee System.pdf (7,330 Kb)  U2 Knee System

CR SYSTEM - Cruciate Retaining

|

- The intact “Posterior Cruciate” Ligament will be retained for this type of implant because it will provide stability for the backward movement of the tibia

- The femoral and tibial component has notches to accommodate the ligaments

- The polyethylene tibial insert has a flat central surface

|

PS SYSTEM - Posterior Stabilized

|

- The Posterior Cruciate Ligament will be removed for this type of implant and it will be replaced by a femoral cam and tibial spine. This will mimic the normal function of the PCL, limiting the forward roll of the femur over the tibia and supporting backward movement of the femur as you bend or flex the knee.

- This Prevents posterior tibial subluxation and enhances knee kinematics

- Has conforming round on round articular geometry that mitigates edge loading and reduces polyethylene damage

|

MB SYSTEM - Mobile Bearing

|

- Designed for potentially longer performance with less wear

- The polyethylene insert in the tibial component can rotate short distances inside the metal tibial tray which promotes less wear. This rotation allows patients a few degrees of greater rotation to the medial and lateral sides of their knee

- Because of this mobility, mobile-bearing knee implants do require more support from the ligaments, surrounding the knee

|

Femoral Component

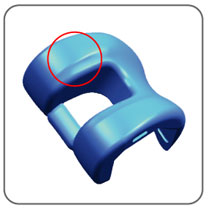

•PS Femoral Component

|

- CoCrMo Casting

- Cemented design

- Five sizes Left and Right

- Matching AP/ML size ratio

- Extended patellar tracking groove

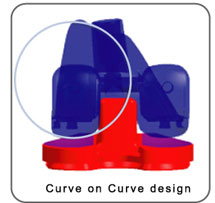

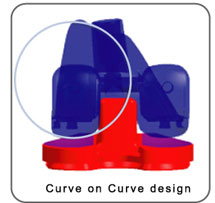

- Curve on curve design on coronal plane

- Multi-radius design on sagittal plane

- Rounded anterior cam to reduce tibial spine wear

- Rotational constraint set at ±13 degrees of freedom

- Fixed intercondye notch width for size interchangeability

- 9mm bone cut at distal and posterior condyles for better ROM

- Less bone resection at femoral box withsafety jumping distance

|

•CR Femoral Component

|

- CoCrMo Casting

- Porous coated and Cemented type are available

- Two fixation legs for orientation and fixation

|

Tibial Insert

•CR/PS Tibial Insert

|

- Cross Linked Polyethylene

- Curve on curve design on both sagittal and coronal planes for PS design

- Minimum 6mm polyethylene thickness

- Rounded anterior spine to reduce wear for PS design

- 5 degrees posterior slope

- Anterior cut off to reduce soft tissue impingement

- Posterior cut off to increase ROM

- Full capture locking mechanism reduce back side wear

|

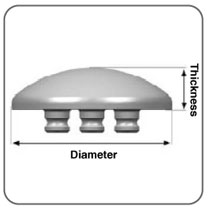

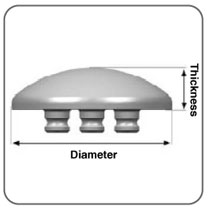

Patella Component

|

- Cross Linked Polyethylene

- Dome shape

- Both ON-SET and IN-SET designs

- 7 sizes available for ON-SET patella (26- 45mm)

- 4 sizes available for IN-SET patella (22-32mm)

- 8-10mm thickness for maintaining bone stock

- 3 pegs design for ON-SET type

|

Tibial Component

|

- Titanium forged

- Cemented design

- 6 sizes available (AP42-55.5mm)

- Precise AP/ML ratio for better bone coverage

- Full capture locking mechanism to reduce back side wear

|

Mobile Type

|

- CoCrMo casting tibial tray

- UHMWPE tibial insert

- Match with PS femoral component

- Rotating platform with central stem

- Highly polished surface

|

Design Rationale

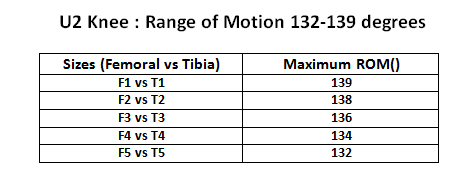

•Range of Motion

|

- Curve-on-Curve Design

Femoral component has varus tilting or life off, it will provide less edge loading thus has less wear of polyethylene tibial insert.

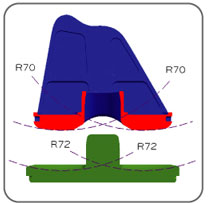

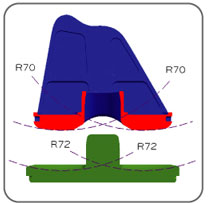

- The best curvature of Curvature of Curve-on Curve Design

It is base on compromising between laxity (freedom of motions) and conformity. The knee with a femoral frontal radius of 70mm, and a tibial frontal radius of 72mm, would satisfy the conflicting needs of both resistance to wear and natural kinematics.

|

•Range of Motion

•Tibiofemoral Sagittal Plane

|

|

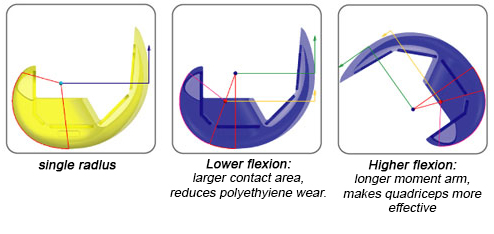

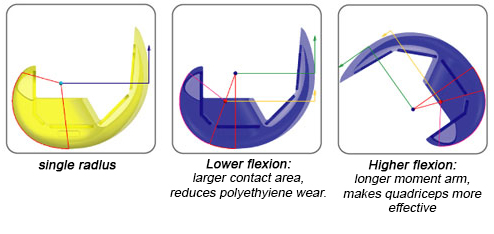

U2 knee select Multiple Radius Design.

The patella moment arm of the Single radius design is longer than that of the Multi- Radius design's extension radius, but shorter than the Multi-Radius design’s flexion radius. It means that the Multi-Radius design makes quadriceps more effective at larger flexion angle.

|

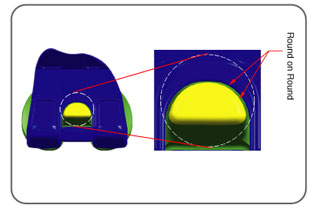

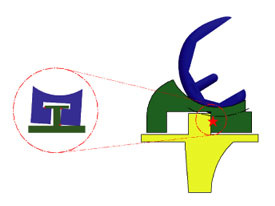

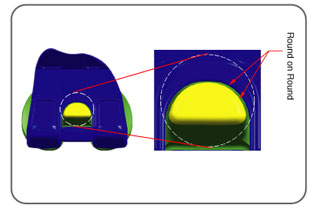

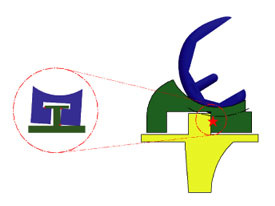

•Round on round spine-cam contact

|

|

To reduce anterior spin wear, U2 PS Knee designed with rounded anterior tibial spine and rounded anterior femoral intercondylar eliminate anterior tibial spine polyethylene wear at rotation and hyperextension.

|

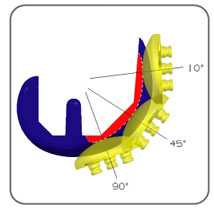

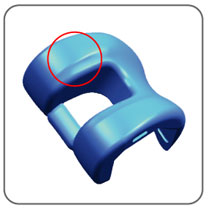

•Extended Patellar Groove

|

|

U2 Knee system extend the patellar groove of femoral component (Exceed 90°) to provide maximum contact at knee deep flexion.

|

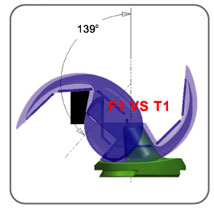

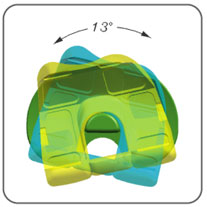

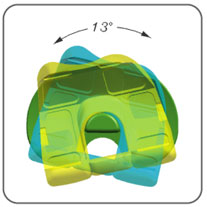

•Rotational Constraint

|

- In rotational constraint consideration; as in human gait an average of 13 degrees internal and external rotations, U2 primary PS Knee system will allow ±13 degrees of rotations.

|

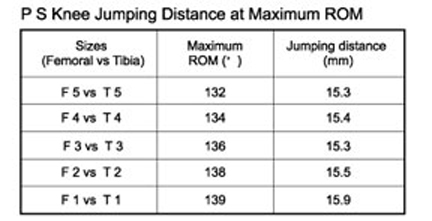

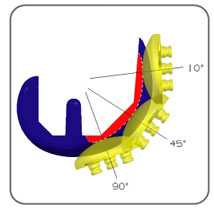

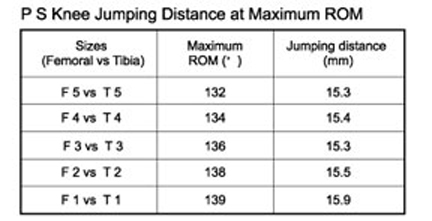

•Jumping Distance

|

|

U2 PS knee offers the highest jumping distance without compromising the bone cutting volume. The jumping distance of U2 Knee's design at 90° of flexion is 16.8mm.

|

•U2 Mobile Bearing

|

|

Rotation + Translation design was reported the impingement wear at translation or rotation stopper mechanism at 5 years post operatively. Also more contact spots or sharp corners are more likely to enhance potential polyethylene wear in translation mechanisms of rotation +translation design.

The U2 MB Knee prosthesis only allows the insert to rotate in the internal-external direction against the baseplate and its insert is of a posterior stabilized design.

|

Back to the Top ^

|